From 40 years, LA CELLINI is a benchmark for the creation of buckle and accessories for the fashion and leather industry all around the world. The company born in 1975 in Milan as a business specialized in the production of handmade accessories; it was brainchild of Aristide Longhi, a goldsmith who was located in the Porta Ticinese area, when it was a place full of handicraft, arts and culture. During the years, new techniques and innovative tools were added to the simple manual skills, and allowed to answer to the growing needs of the customers. The passion for the handicraft and traditions and the willingness of communicate the value of the Made in Italy, merge strategically, with creativity and innovation, in LA CELLINI, that today becomes the synonymous of high quality brass accessories. LA CELLINI doesn’t leave anything to chance: all the supply chain, from the planning to the raw material’s processing, till the finished product is made inside the company in order to guarantee the highest quality, through the control of every single production stage. Our Company doesn’t want to agree to compromises: every single choice is made with the main objective of the full satisfaction of our customers. Thanks to this approach, today we have the honour to supply some of the more famous and important Italian and international fashion brands.

Our Products

Founder

Aristide Longhi

The company born in 1975 in Milan as a business specialized in the production of handmade accessories; it was brainchild of Aristide Longhi, a goldsmith who was located in the Porta Ticinese area, when it was a place full of handicraft, arts and culture.

Passion and craftsmanship

Brass

A passion for craftsmanship, tradition and a willingness to bear daily witness to the value of Made in Italy

Nothing is left to chance

Highest quality

Our Company doesn't want to agree to compromises: every single choice is made with the main objective of the full satisfaction of our customers.

Our Process

PRODUCT DESIGN

Planning and prototyping of products designed for production.

START PRODUCTION

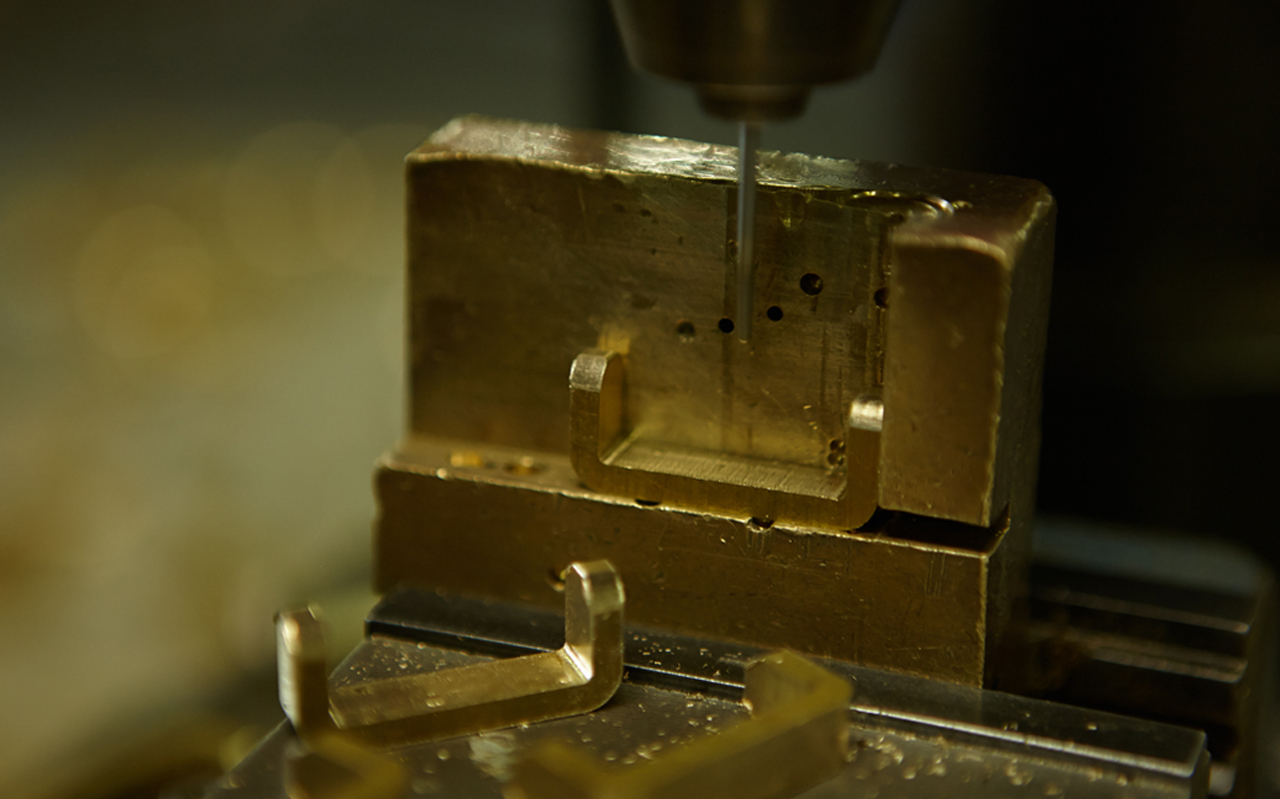

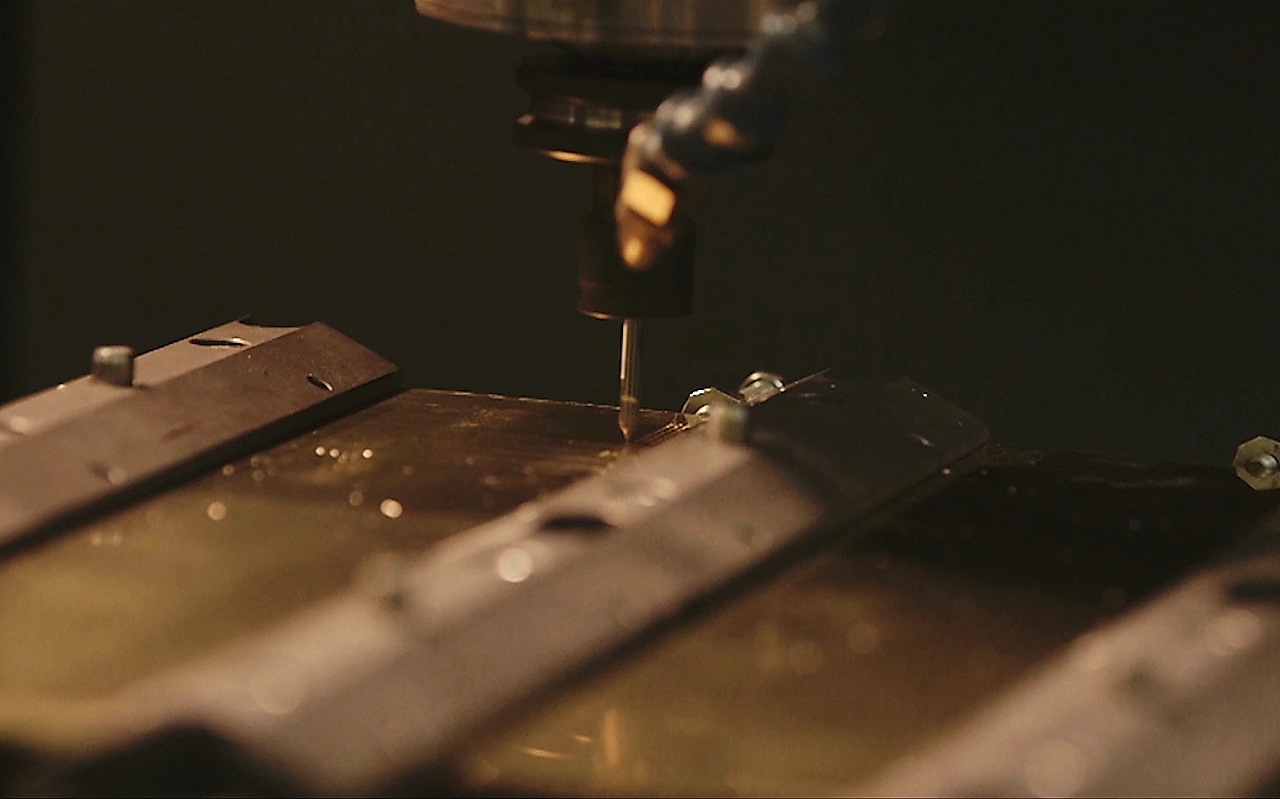

From the numerical control to the hot printing and the die-casting.

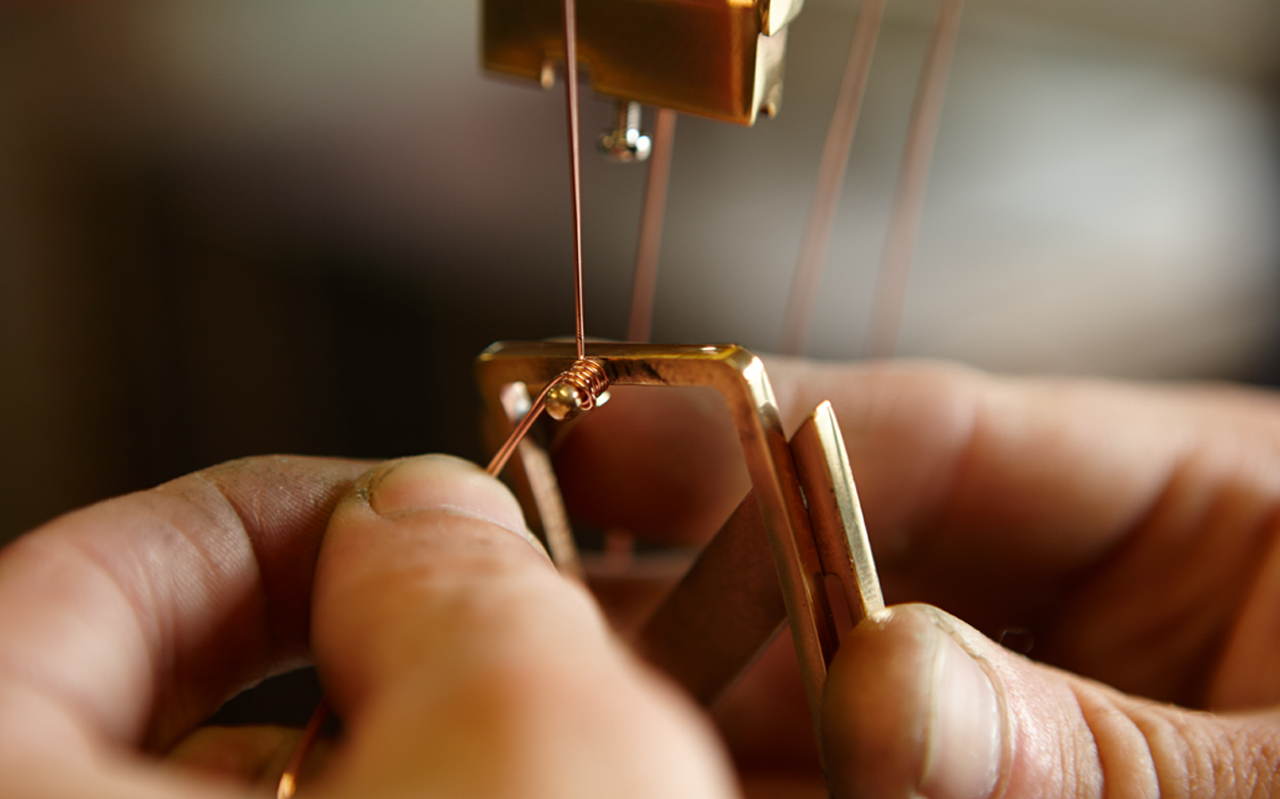

SOLDER - PULIMENTATURA

Welding service, handmade and accurate, for the details. Grinding process and manual cleaning of every single piece in order to give a unique and refined product.

GALVANISATION - PAINTING

Galvanisation process for the more refined finishing: nickel, palladium, gold, ruthenium, and much more. Product’s painting.

CUSTOMIZATION - QUALITY CONTROL

Product’s customization through engraving or laser decoration. An accurate and meticulous quality control of all the production stages.

English

English